“We provide high-quality products and servicesin order to fulfill the dreams of our customers and are committed to pursuing environmental friendliness and meeting our social responsibilities.”

Properties

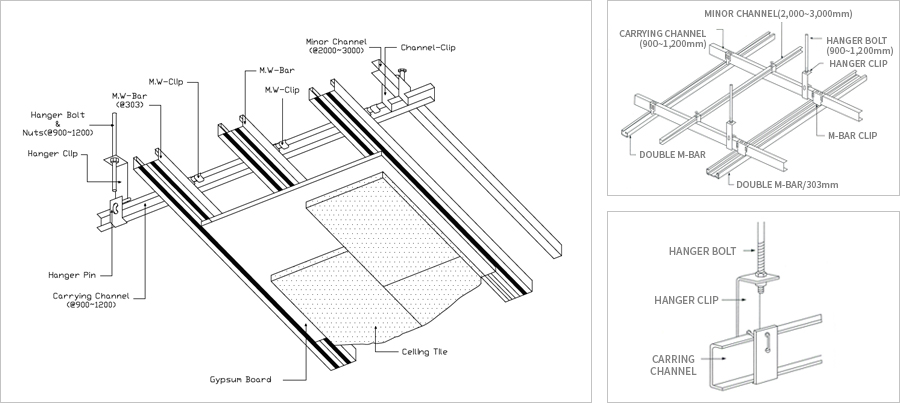

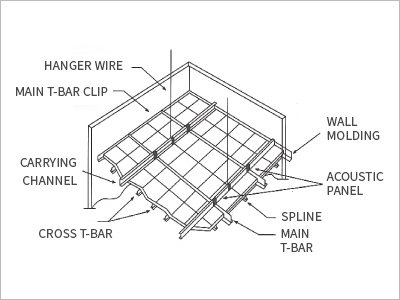

With this system, ceiling boards can be tightly joined and the high soundproof effect can be achieved through sticking plates doubly using gypsum boards and rock wool sound-absorbing boards, in particular. This system is widely used for ordinary offices, banquet halls, apartments and expensive houses.

Quality of Ceiling Suspension

Material: Galvanized sheet iron (KS D 3506), color galvanized sheet iron (KS D 3520)

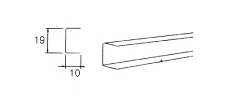

M-BAR

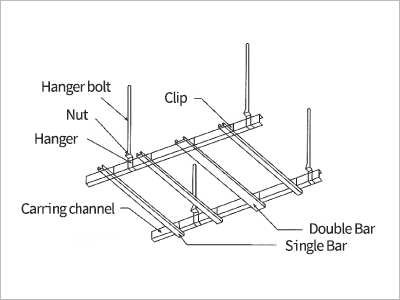

1. Materials of Ceiling Suspension(M-bar system)

① Phenomenon of sub-materials, stability

1) Lateral bending: Less than 2L/1,000mm

2) Curving: Less than 2L/1,000mm

② Loading strength

1) Downward load

– M-bar: Maximum deformation volume less than 10mm / residual bending quantity less than 2mm

– Carrying channel: Maximum deformation volume less than 10mm / residual bending quantity less than 2mm

2) Upward load: Maximum deformation volume less than 5mm

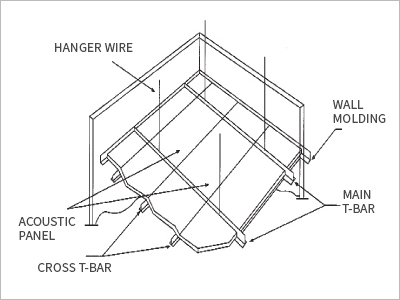

Materials of ceiling system (T-bar system) direct hanging

2. Materials of Ceiling Suspension (T-bar system)

① Straightness

1) Bending: 1.30mm/M

2) Deflection: 1.30mm/M

3) Twistedness: 2 /M

② Minimum load of main T-bar

| Table: Division | minimum load (kg/m) | |

|---|---|---|

| direct hanging | indirect hanging | |

| Light-Duty | 7.4 | 3.0 |

| Intermediate-Duty | 17.9 | 5.1 |

| Heavy-Duty | 23.8 | 11.9 |

Materials of ceiling system (T-bar system) indirect hanging

3. Quality of component materials

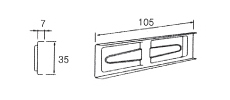

② NUT : Do electrogalvanizing nuts whose diameter is longer than 7.7mm.

③ Hanger : Galvanized sheet iron whose thickness is more than 0.6mm

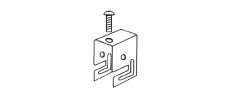

④ M-BAR Clip (can be used for Single& Double Clip)

-Galvanized sheet iron whose thickness is more than 0.6mm

-Galvanized sheet iron whose thickness is more than 0.8mm

⑤ M-BAR Joint : Galvanized sheet iron whose thickness is more than 0.5mm

Names of Component Materials for Ceiling Suspension

| Table: Name | signal | standard | way of assembling | use | |||

|---|---|---|---|---|---|---|---|

| W | H | T | |||||

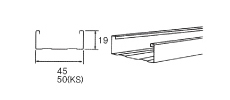

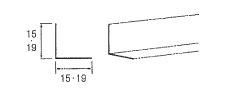

| single bar | CS-19 CS-25 |

25 25 |

19 25 |

0.5 0.5 |

CS-19, CW-19, CC-19 CS-25, CW-25, CC-25 |

Bar load capacity: up to 30kgf Bar load capacity: up to 50kgf |

|

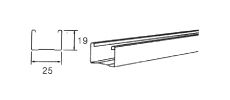

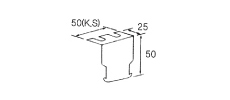

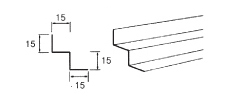

| double bar | CW-19 CW-25 |

50 50 |

19 25 |

0.5 0.5 |

refer to single bar | ||

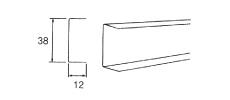

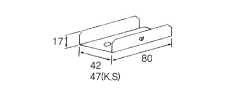

| carrying channel | CC-19 CC-25 |

38 38 |

12 12 |

1.2 1.6 |

refer to single bar | ||

| T-bar | T-38 T-25 |

38 38 |

1. Light duty system: For commercial buildings without expectation of load ofceiling tiles or panels. 2. Intermediate duty system: Mostly for ordinary commercial buildings with expectation of slight ceiling load by lighting and air-conditioning systems 3. Heavy duty system:Mostly for commercial buildings heavier than regular buildings in terms of quantity and weight, such as ceiling structure (lighting and air-conditioning systems) |

||||

Ceiling System Parts Lists

METAL THICKNESS(mm) : 0.4, 0.45, 0.5

LENGTH(mm) : 4,000

METAL THICKNESS(mm) : 0.4, 0.45, 0.5(K.S)

LENGTH(mm) : 4,000

METAL THICKNESS(mm) : 1.0, 1.2(K.S)

LENGTH(mm) : 4,000

METAL THICKNESS(mm) : 1.0, 1.2(K.S)

LENGTH(mm) : 4,000

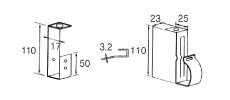

METAL THICKNESS(mm) : 0.5

METAL THICKNESS(mm) : 0.5

LENGTH(mm) :

METAL THICKNESS(mm) : 1.2

METAL THICKNESS(mm) : 1.2

LENGHT(mm) :

METAL THICKNESS(mm) : 8/3(in)=¢9mm

LENGTH(mm) : 1000, 2000, 3000 (made-to-order)

QUANTITY PER SQUARE METER : @900X@1200

METAL THICKNESS(mm) : 2.0

LENGTH(mm) : 50, 100, 150, 200

METAL THICKNESS(mm) : 1.0, 1.2

LENGTH(mm) : 3,000

COLOR : Dancing halls, nutbrown, white

METAL THICKNESS(mm) : 1.0, 1.2

LENGTH(mm) : 3,000

COLOR : Dancing halls, nutbrown, white

Detailed construction drawing